Bhopal, the capital city of Madhya Pradesh, is on the brink of a revolutionary change in its transportation system with the Bhopal Metro Rail Project. Aimed at addressing the growing demands of urban transportation, this under-construction Mass Rapid Transit System (MRTS) promises to not only ease traffic congestion but also improve air quality and provide a robust, efficient transit solution for the city’s burgeoning population.

Project Overview

The Bhopal Metro project, executed by the Madhya Pradesh Metro Rail Corporation Limited (MPMRCL), encompasses two primary lines: the Orange Line and the Blue Line. The project is overseen by general consultants DB, Geodata and Louis Berger.

Key Details:

● Client: Madhya Pradesh Metro Rail Corporation Limited (MPMRCL)

● General Consultant: DB Geodata & Louis Berger

● Project Scope: Includes elevated and underground stations, depots, elevated sections, underground tunnels and ramps.

Phase 1 Lines

Orange Line:

● Route: AIIMS to Karond Circle

● Elevated Section: 13.35 km

● Elevated Stations: 13

● Interchange Station: 1

● Underground Tunnel: 3.39 km

● Underground Stations: 2

Blue Line:

● Route: Bhadbhada Square to Ratnagiri Tiraha

● Elevated Section: 14.16 km

● Elevated Stations: 13

● Interchange Station: 1

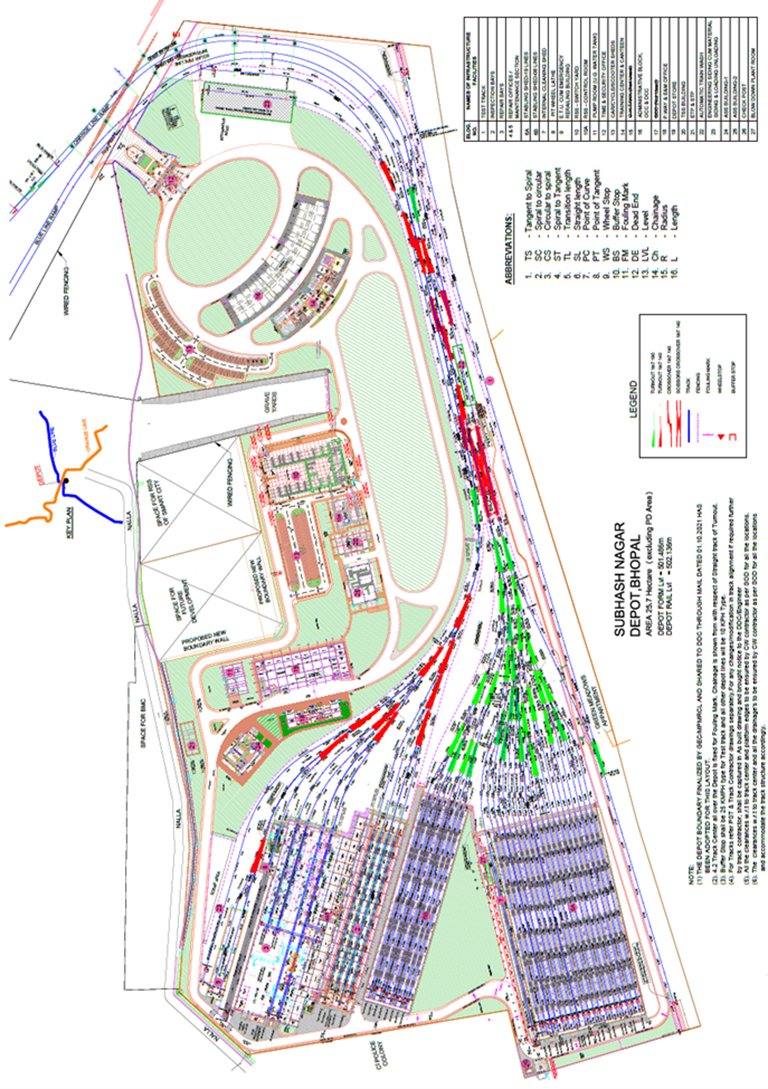

Depot Overview

The Bhopal Metro features a full-fledged depot for Phase I, accommodating both the Orange and Blue lines. The depot, spread over an area of 26 hectares at Subhash Nagar, is equipped with all the necessary facilities for stabling, operation control, and maintenance of rolling stock, signaling and telecommunications (S&T), platform screen doors (PSD), automated fare collection (AFC), traction and permanent way (P-way). It also houses an operation control center and a training center to manage the operations of the entire Phase I of the Metro Rail Network.

Overall layout of Bhopal Metro rail

Major Facilities in the Depot

- Administrative cum Operation Control Centre & Depot Control Centre Building:

○ This building is designed for administrative purposes to monitor and control the operation and maintenance of the metro rail system. It includes a crèche, medical room, prayer room, training rooms, server operations and signaling repair rooms. It also houses a canteen, crew booking center and a sperate building.

2. Operation Control Centre (OCC):

○ From the OCC, train movements are monitored and controlled throughout the metro rail network in the main line.

3. Depot Control Center (DCC):

○ The DCC monitors and controls train movements throughout the depot, including scheduled/unscheduled shunting and inspection/maintenance activities in different sheds and lines.

4. Stabling Shed:

○ Equipped with stabling lines and platforms to accommodate train sets, facilitating regular checks and operational requirements. It is a covered shed with capacity for stabling 27 train sets of 6 cars each during night and non-peak hours. All lines have the facility of third rail traction power for train movement.

5. Inspection Bay Line/Shed:

○ This shed has four inspection lines with facilities such as a sunken floor for underframe inspection, roof access platform, stinger for traction, EOT crane, and compressed air lines. Routine inspections (Type B & Type C) will be performed here at intervals of 15 days, 30 days, and 90 days for all train sets.

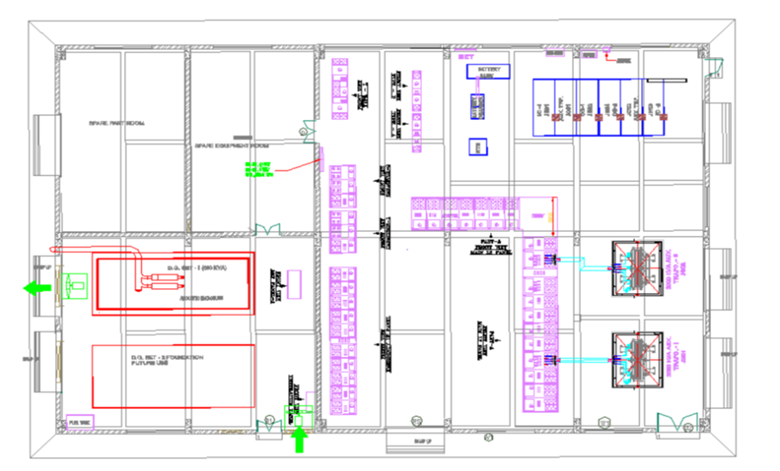

6. Workshop/Repair Bay Line/Shed:

○ Equipped with four lines, this shed includes under-floor lifting jacks, mobile lifting jacks, a bogie turntable, a traction motor cleaning room, a bogie test bench, compressed air room, EOT cranes and compressed air. All types of maintenance (mechanical, electrical, and electronic), including intermediate overhauling (IOH), periodic overhauling, and breakdown repair of rolling stock, will be carried out here.

7. Pit Wheel Lathe Shed:

○ This facility has one line for a 6-car train set, equipped with an underfloor wheel lathe, EOT crane and compressed air line. Rolling stock wheel profiling will be performed here without decoupling the coach or dismantling the wheel set from the rolling stock, saving significant maintenance time.

8. Emergency and Auxiliary Vehicle Maintenance Shed (ETU Shed):

○ With two lines, this shed is equipped with an EOT crane and pits for underframe inspection. All types of maintenance and services will be performed here for emergency and auxiliary vehicles used for rescue and support operations, such as battery shunters, shunting locomotives, rail-cum-road rescue vehicles, and wagons.

9. Automatic Train Wash Plant:

○ This plant is located on one of the depot entry lines from the main lines and shall perform external cleaning of trains from the sides and rooftop while they move at a speed of 3 to 5 KMPH. It also cleans the train’s front and rear ends, with trains stopping twice at designated points on the washing bed. All cleaning activities are automated, requiring no human intervention for trains returning from the main line to the depot at an interval of three days.

10. Test Track:

● A straight line of approximately 850 meters with traction facilities shall be available in the depot to test train speed, braking, acceleration, and deceleration under different conditions. This testing is performed after the arrival of new train sets from the factory and/or after major repairs before the trains are sent to the main line for operations.

11. Internal Cleaning Shed:

● This shed has one line for a 6-car train set, equipped with a roof access platform, underframe access, blowdown plant, and high-pressure jet for cleaning. It will be used for internal and external deep cleaning of train sets every 30 days.

12. Central Depot Store:

● This facility shall be used for storing all spares parts related to the maintenance of rolling stock, S&T, traction, AFC, lift and escalators and electrical and mechanical (E&M) work.

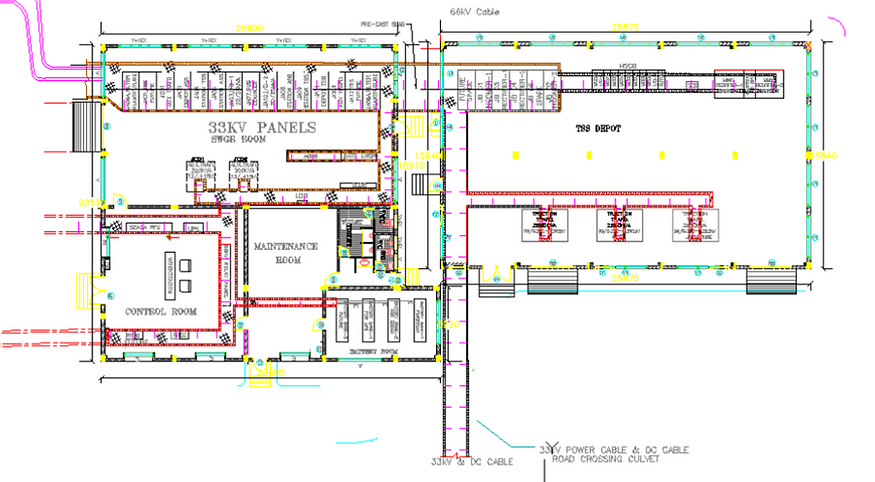

13. Traction Substation:

● This substation receives 33 KV power from a receiving substation and supplies 750 V DC as third rail traction for train movement, as well as 415 V to the auxiliary substation through a step-down transformer.

14. Auxiliary Substation:

● This substation provides 415V power to all building and sheds (lighting, power supply to plant and machinery, etc.) other than traction within the depot.

15. Security:

● A permanent boundary wall at least 3 meters high with a concertina coil fence, lights, and CCTV cameras ensures depot security.

Conclusion

The Bhopal Metro Rail Depot represents a modern urban infrastructure marvel, featuring state-of-the-art facilities, thoughtful design and a commitment to sustainability. The depot is equipped with the latest technology and equipment for operation control and comprehensive maintenance of rolling stock, S&T, PSD, AFC, traction, track, and E&M systems. This ensures enhanced service quality and extended service life for the rolling stock and its supporting systems, promising a better future and uninterrupted urban transit system in Bhopal.

Comments

Post a Comment